Introduction

What products and materials are we referring to?

What is BS 6515:1984?

It is a British Standard that relates to the manufactuer of polyethylene damp proof courses, intended for use in masonry construction. It covers material composition, thickness, finish and permeability of the material.

BS 6515:1984 contains an Appendix giving the recommended uses for polyethylene DPC’s, and notably recommends that these products are not used as a solution against the downward movement of water e.g. cavity trays.

More recent standards, such as BS8215:1991 and PD6697:2019 (a published document sitting alongside BS EN 1996-1-1), offered a variation – in that such materials could be used, provided they were installed, detailed and sealed correctly in line with manufacturers guidance.

However, the issue is that polyethylene materials are often produced without any manufacturers supporting guidance nor do they undergo testing as cavity tray installations, as they are only intended to be used for ‘simple’ damp proofing situations. So installed to deal with:

A) Upward movement of water e.g. linear DPC at the base of a wall and;

B) Horizontal movement of water e.g. vertical applications at window and door reveals.

What are the warranty provider's concerns?

Warranty stance

What developers should action after reading this document?

Developers should ensure that design teams and specifiers check the guidance provided by manufacturers of flexible DPC materials before use.

The manufacturer’s literature should explicitly state the suitability of their product for use as a cavity tray and their recommendations for appropriate use and installation should be followed. The advice of the manufacturer will typically be aligned with the guidance of:

- BS 8215:1991 Code of practice for design and installation of damp proof courses in masonry construction - for design.

- -BS 8000-3:2020 Workmanship on construction sites - Code of practice for masonry - for installation.

Where flexible DPC materials are to be used as a cavity tray, they must:

- Have third-party certification (BBA or similar UKAS accredited body) confirming their suitability for use as a cavity tray in the situation they are being proposed. A material that carries 3rd Party Accreditation will often have supporting ancillaries e.g. pre-formed corner ‘cloaks’ and adhesive tapes for use as a cavity tray.

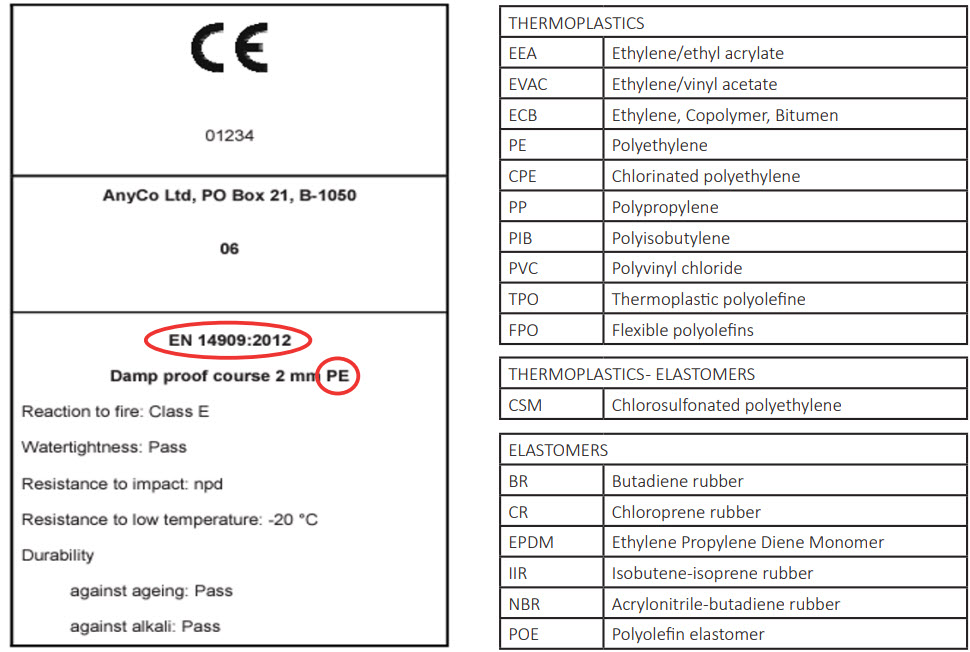

- Have supporting evidence in the form of a Declaration of Performance to BS EN 14909:2012. This standard stipulates the characteristics required of flexible sheet damp proof courses for buildings. It details the requirements and test methods to determine conformity of the products.

Developers should also ensure that buyers and suppliers of materials for their sites are aware that where the material is polyethylene, that meeting the requirements of BS 6515 alone is not enough to support their use as a cavity tray.

Appointed sub-contractors should not substitute materials and site teams should check the material on site against specification given by the designer or Engineer against the Declaration of Performance information – this certification should include reference to BS EN 14909:2012 and include one of the ‘Product Designation Codes’ given within that standard to enable a clear determination.

Developers should also ensure that site teams operate appropriate quality assurance checks which have a stage that looks at cavity trays, and the obvious issues that cause failure.

For example, a cavity tray that is not laid on mortar, e.g. dry laid, can result in movement in the wall where the mortar bond is not created. It can also allow moisture to track under the material, and where this is above an opening, often lead to visible moisture ingress and damp patches on reveals and wall areas below the cavity tray.

Also look out for laps that are not sealed, poor detailing around corners, wind post penetrations leaving open joints or cavity trays that do not terminate in a stopped end. Ideally a pre-formed stop end but more likely to be a perp joint 'turn-in' of the material should be used to terminate a discontinuous cavity tray installation.

Subscribe to be first to hear about our technical updates

Download a PDF version of this article

Disclaimer

This technical document has been prepared by Premier Guarantee exclusively for the benefit of our registered customers. Its sole purpose is to provide guidance on the utilisation and interpretation of technical requirements pertinent to the warranty cover offered by Premier Guarantee.

Please note that this document is not intended for circulation or use beyond the aforementioned purpose. The information presented herein is for general guidance only and does not constitute professional advice. Registered customers and any other party accessing this document are advised not to rely solely on the information contained within.

Nothing in this document is intended to establish, nor should it be construed as creating, any contractual or legal obligations. In the event that any third party chooses to rely on the information provided, they do so entirely at their own risk. Premier Guarantee explicitly disclaims any duty of care or liability that may arise from the use of or reliance on this document by any third party, howsoever arising.

properties.trackTitle

properties.trackSubtitle